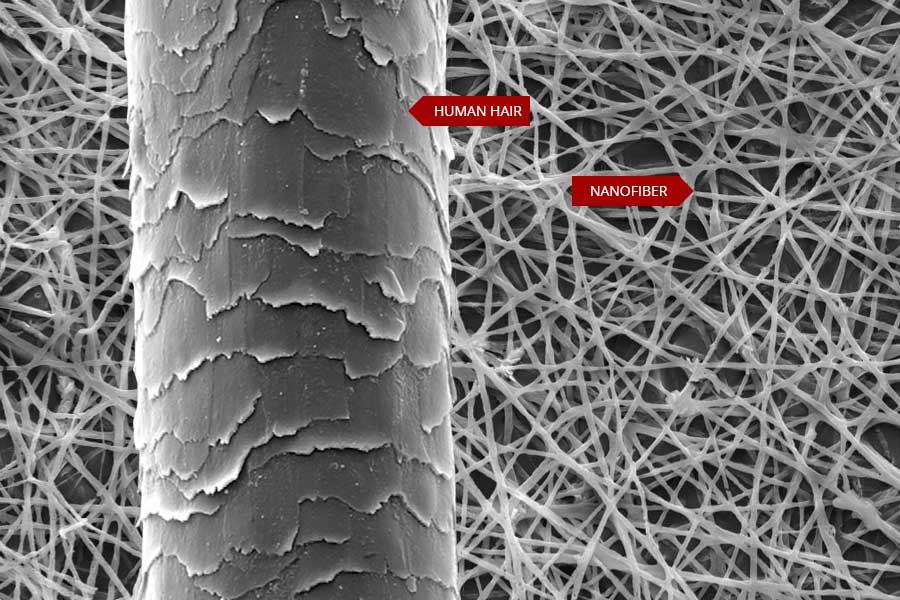

“Nanofibers are defined as fibers with diameters less than 100 nanometres the textile industry ,this definition is often extended to include fibers as large as 1000nm diameter.

Nanofibers range in diameter of 2-600 nanometres and are very difficult to see with the naked eye so they are studied using magnification.

Nano layer is a 3-dimensional fibre composed of stacked web of nanofibers. Such nanofibers coatings and nano membranes are produced through proprietary electrospinning process using various polymers. The interconnected and porous nanofibers have enormous surface area for its volume and has shape of a mesh.

Due to these unique features, it is very thin and light weighted. It also has high penetrability and permeability, but is also effective at resisting liquid and wind. These properties are particularly advantageous for high efficiency filter materials, energy storage materials, tissue engineering, biomedical application, micro-electronic mechanical system materials, nano complex materials and other applications.

Further, by applying nano layer to regular textile, it enhances functionality to be used as technical textiles in various application.

Nanofibers can be produced by …

Some nanofibers can be made by melting polymers and spinning or shooting them through very samll holes.As the fibers spins out it stretches smaller and smaller

Cotton candy is made by heating syrup to a high temperature and then the liquid is spun out through tiny holes .as the fiber spins it is pulled thinner and thinner.It cooles,hardens and presto!! Cotton Candy !

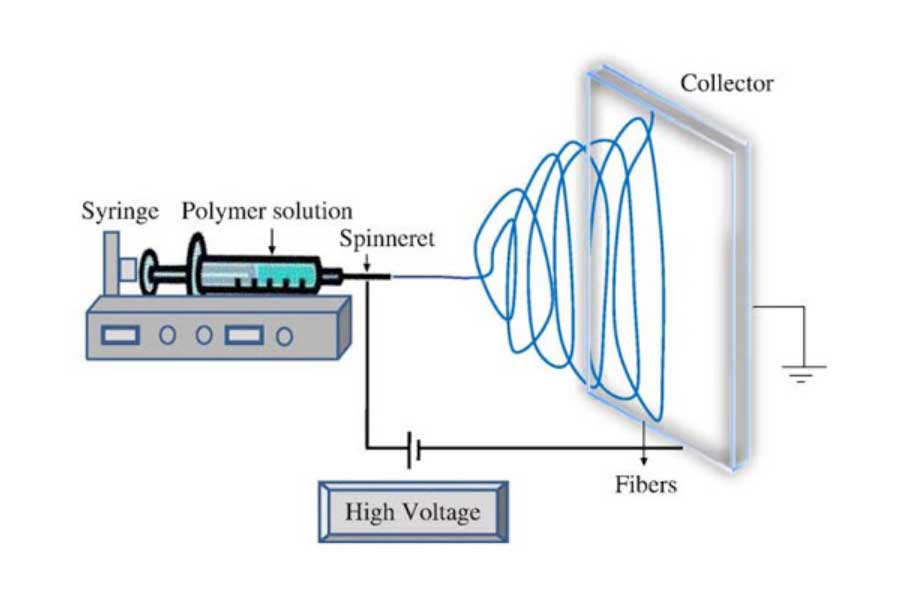

The smallest nanofobers are made by ELCTRPSOINNING solution of polymers.These solutions are place in pipette or syringe with a small wire inserted.The wire will serve as an electrode which is hooked to high voltage power supply.

Acollection plate where fibers will land and deposit is attached to the ground of the power supply.

Generally, polymeric nanofibers are produced by an electrospinning process.

Electrospinning is a process that spins fibers of diameters ranging from 10nm to several 100nm.This method has been known since 1934 when the first patent on electrospinning was filed. Fibers properties depend on field uniformity, Polymer viscosity, electric field strength and distance between nozzle and collector.

Advancements in microscopy such as scanning electron microscopy has enabled us to better understand the structure and morphology of the nanofibers.

An electric field pulls on a droplet of polymer solution at the tip of the syringe and pulls out a small liquid fiber.It is pulled thinner and thinner as it approches the collection plate.

Electropsinnng a polymer solution to produce nanofibers :

Polymer solution can be electrospun beasue of their long repeating units.

Too high : No fiber deposition

Too Low: Chance of Arching

Too high : Chance of arching

Too Low: not enough pull to form fiber

Diameter of fiber changes

Too High: Viscosity will not allow fiber formation

Too Low: Beads of polymer will form

Too High: Beads form

Too Low: Inconsistent fiber deposition